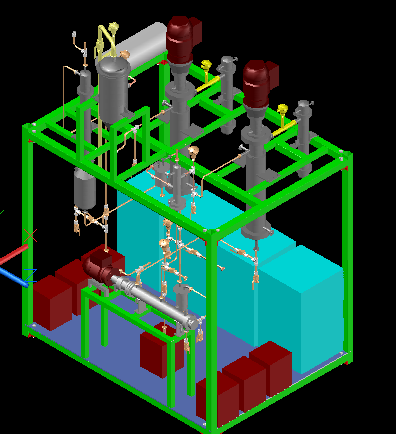

Azelaic acid is widely used intermediate in the pharmaceutical industries for the preparation of ointments, cosmetics, and commodity chemicals. Azelaic acid finds its applications to treat mild to moderate acne, skin brightening agent and its derivatives are also used to antibacterial, keratolytic, comedolytic, and anti-oxidant activity. NCL has developed a continuous process for its synthesis via Ozonolysis of unsaturated fatty acids and demonstrated at pilot plant scale. The reactions involves using ozone, oxygen, oleic acid and a few solvents. It yields Azelaic acid (Product) and Pelorganic acid (by-product). The process is free of any metal catalysts and includes complete recycle and reuse of the solvents, making it a green process.